Self-Assembling Materials Could Be the Breakthrough EV Batteries Have Been Waiting For

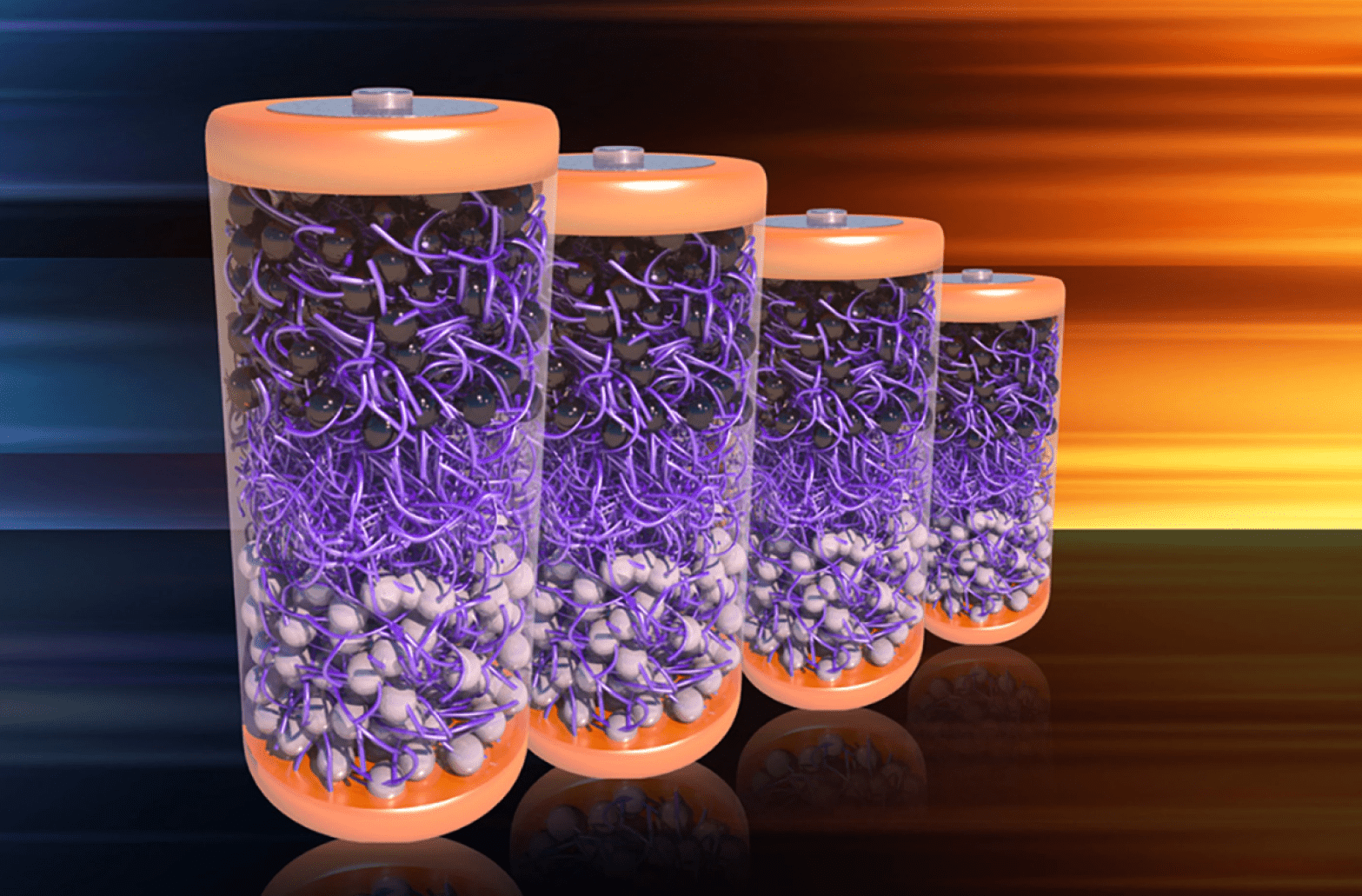

A depiction of batteries made with MIT researchers’ new electrolyte material, made from a class of molecules whose chemical structures and stability mimic Kevlar

Image courtesy of the researchers

In the race to electrify transport, one of the biggest challenges isn’t how far an EV can go, it’s what happens to its battery when it can’t go anymore.

Today’s electric vehicle boom risks becoming tomorrow’s mountain of battery waste. But a new discovery from MIT could change that. Researchers have developed a self-assembling, recyclable battery material that literally takes itself apart at the end of its life, turning the messy, complex world of battery recycling into something closer to magic.

The material, an electrolyte made from aramid amphiphiles (AAs), molecules that self-assemble in water and mimic the chemical stability of Kevlar, allows the battery to disassemble when placed in an organic solvent. Instead of shredding and smelting a spent battery, this innovation enables each component to simply separate for reuse, dramatically simplifying recycling.

“Our approach is to start with easily recyclable materials and figure out how to make them battery-compatible,” explains lead researcher Yukio Cho, PhD ’23. “Designing batteries for recyclability from the beginning is a new approach.”

Designing for Disassembly

Traditional lithium-ion batteries are made up of tightly bonded layers, cathode, anode, and electrolyte, which makes separating materials difficult. Recycling them requires harsh chemicals, high temperatures, and high costs.

The MIT team’s approach flips that script. Their electrolyte, made from self-assembling nanoribbons, acts as a stable, solid-state conductor during operation, but when immersed in liquid, it breaks back down to its original molecules.

As Cho puts it, “When you want to recycle the battery, the entire electrolyte layer can fall off naturally, and you can recycle the electrodes separately.”

The process is so fast that Cho compares it to watching cotton candy dissolve in water.

Built from Strong, Sustainable Chemistry

The innovation is as elegant as it is practical. The nanoribbons are formed when the AAs, which include polyethylene glycol (PEG) chains that help conduct lithium ions, are exposed to water. Within minutes, millions of nanofibers form and intertwine, creating a gel-like network that can be hot-pressed into a solid material.

This structure combines flexibility for ion transport with the toughness of Kevlar, ensuring the material performs under the mechanical stresses of an operating EV battery.

Early Promise, Big Potential

While the prototype doesn’t yet outperform today’s commercial batteries, the implications are enormous. The research proves a new principle, one where batteries are designed for recyclability from day one.

This approach could lead to a new generation of closed-loop EV batteries where lithium, nickel, and cobalt are recovered and reused at scale.

It could also have major supply-chain implications. As Cho notes, “If we can start to recycle lithium-ion batteries from battery waste at scale, it’ll have the same effect as opening lithium mines in the U.S.”

Why It Matters for Fleets and the ZeroMission Ecosystem

At ZeroMission, we see innovations like this as a cornerstone of the FleetOps360° intelligence ecosystem. Fleets are already under pressure to electrify, but sustainability doesn’t stop at the plug. Ensuring that every kilowatt-hour and every gram of lithium is reused is the next frontier.

Designing batteries for circularity reduces raw material dependency, stabilises costs, and reinforces energy security. It also aligns perfectly with ZeroMission’s mission: to make every fleet decision smarter, cleaner, and more efficient, from procurement to recycling.

As we continue building the digital twin ecosystem for modern transport, breakthroughs like MIT’s self-assembling battery materials demonstrate that sustainability and intelligence go hand in hand.

Because in the fleets of the future, even the batteries will know when it’s time to let go.